SYSTEM

Production Line

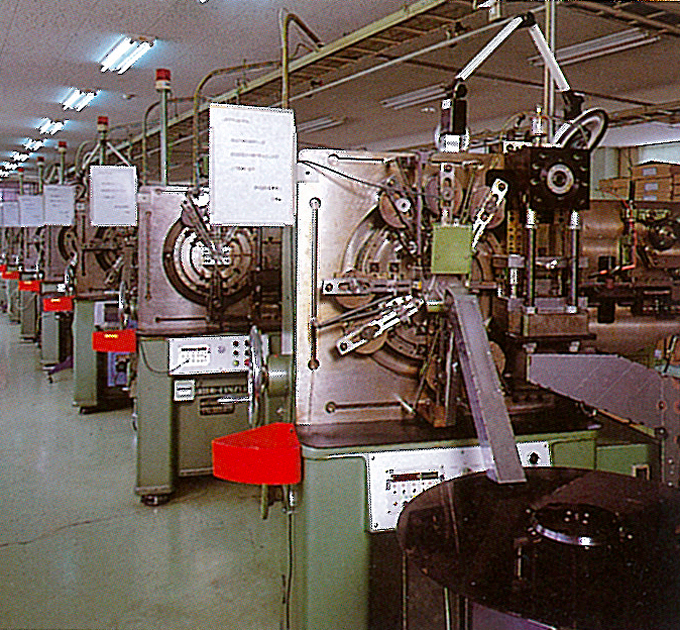

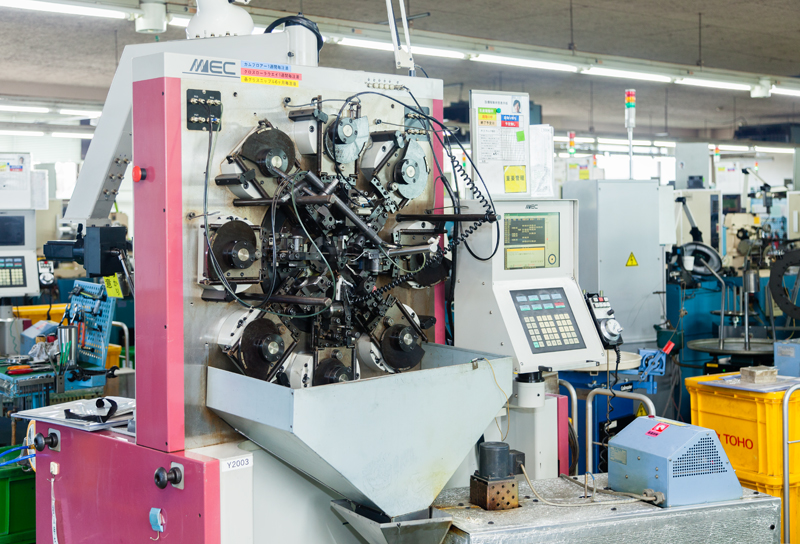

Wire Spring Department

Multi-Forming Department

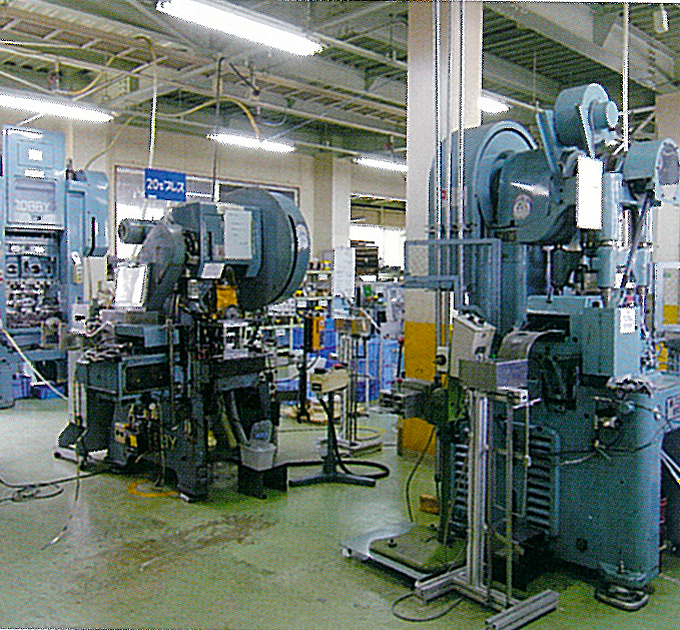

Press Department

Medical Products Department

The micro springs that are used for super precision equipment are manufactured in the clean production room. This room prevents dust or dirt from contaminating the manufacturing process of the springs allowing us to maintain a stable quality of our products.

Trial Production Department

Small-lot products, prototypes, and complicated products are made carefully by hand. They are made by skilled and experienced engineers.

Design and Development Department

We developed all the machines and products in-house such as press tooling molds, multi-forming molds, streamlined machines, and spring manufacturing machines.

Main Equipment

Wire Spring

| NC Spring Machines | 82 units | max wire diameter 4.0 |

|---|---|---|

| NC Coiling Machines | 24 units | max wire diameter 2.6 |

| Coiling Machines | 11 units | max wire diameter 1.0 |

| Self-Developed NC Spring Machines | 9 units | max wire diameter 0.8 |

| Spring Polishing Machines | 4 units |

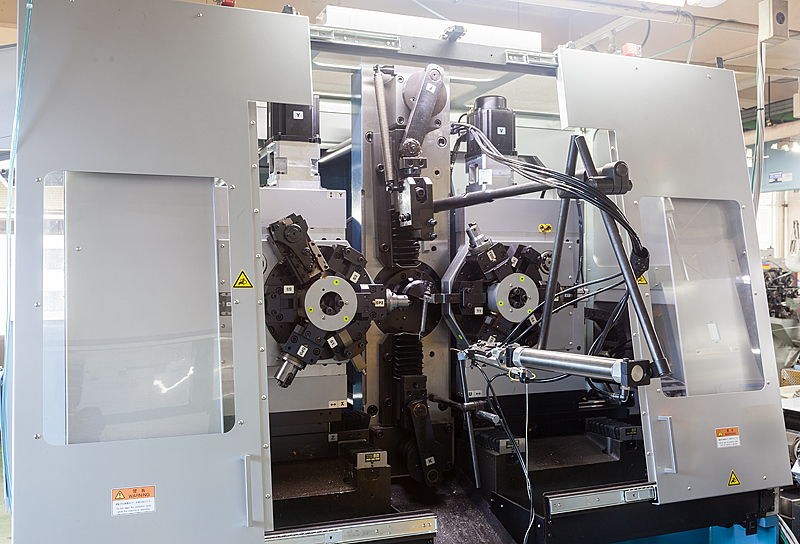

NC Spring Formers

Spring Forming Center

Tension Spring Machines

Long Wiring Coiling Equipment

Long Wiring Coiling Equipment

Micro Spring Machines

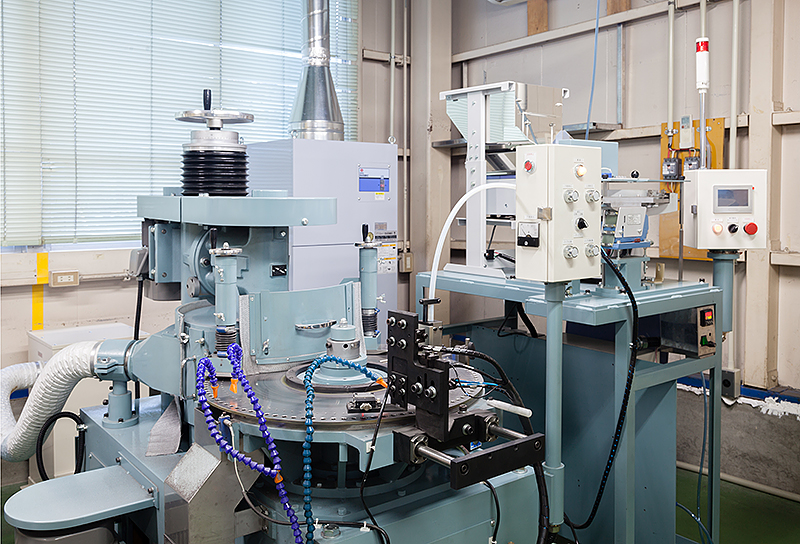

Automatic Polishing Machines

Press Machines

| Automatic Press Machine | 8 units | max 60t |

|---|---|---|

| Hydraulic Press | 9 units | max 10t |

| Multi-Forming Machines | 12 units | max 30t |

| Barrel Polishing Machines | 2 units | |

| Hydrocarbon-Based Cleaning Equipment | 2 units |

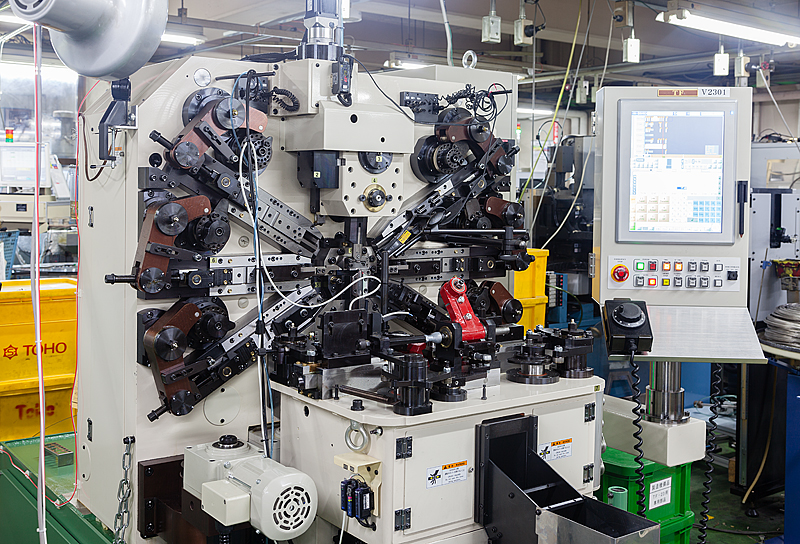

Multi-Forming Machines

Press Machines

Hydrocarbon-Based Cleaning Equipment

Precision Sheet Metal Processing

| Turret Punch Press | 1 unit | |

|---|---|---|

| Press Brakes | 2 units | max 15t |

| Spot Welder | 1 unit | |

| TIG Welder | 1 unit | |

| Tapping Machine | 1 unit |

Self-Developed Equipment

End Treatment Machines

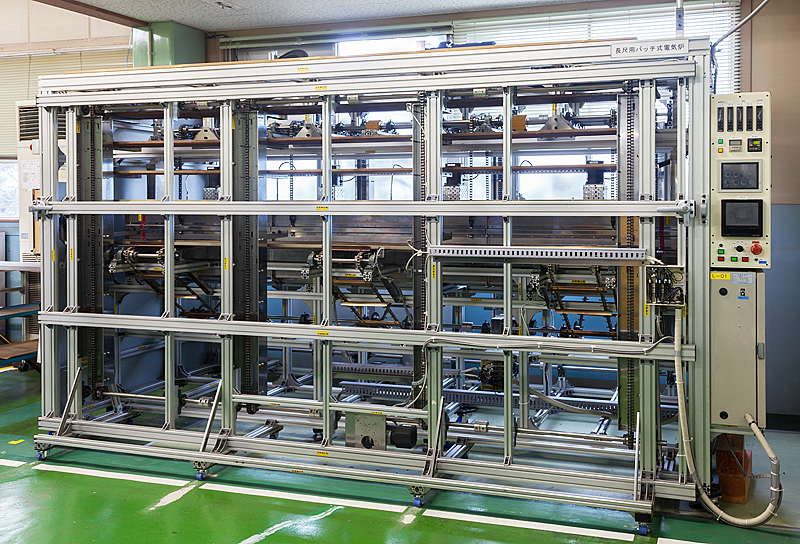

Self-Developed Semi-Automatic Batch Type Electric Furnaces

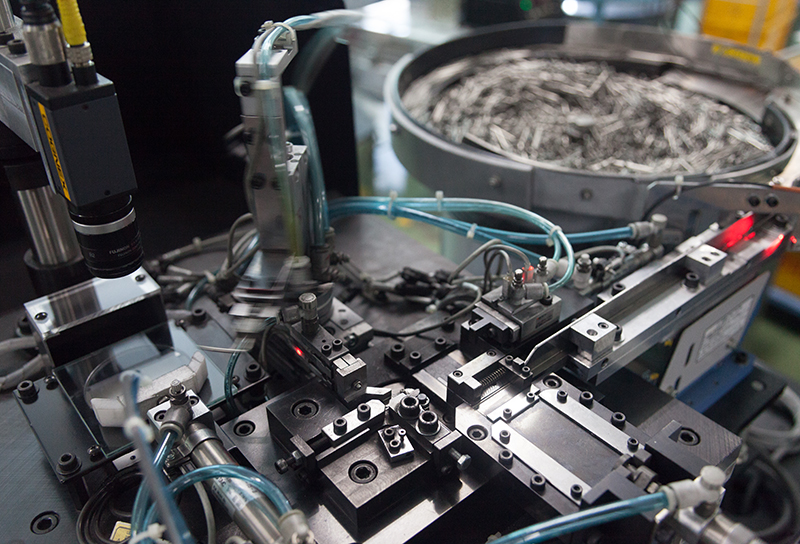

Automatic Bending & Camera Sorters

Full-Automatic Line (Coiling, Heat Treatment, Wrapping)

Heat Treatment

| Batch Type Electric Furnaces | 3 units |

|---|---|

| Conveyor Type Electric Furnaces | 8 units |

| Spiral Vibration Electric Furnace | 1 unit |

| Conveyor Shaker Hearth Electric Furnaces | 11 units |

| Self-Developed Conveyor Shaker Hearth Electric Furnaces | 35 units |

| Self-Developed Small Electric Furnaces | 3 units |

| Self-Developed Batch Type Electric Furnace For Long Size | 1 unit |

Inspection

| Compression Tension Springs Testing Machines | 7 units | 0.01gf – 50kgf |

|---|---|---|

| Torsion Springs Testing Machines | 2 units | 0.1gf – 50kgf |

| Self-Developed Spring Endurance Testing Machines | 2 units | |

| Projectors (dia. 300mm / dia. 500mm) | 15 units | |

| Digital Micro Scopes | 3 units | max x1000 |

| Hardness Testers | 2 units | |

| Image Size Measurers | 2 units | |

| Scanning Electron Microscope (SEM) | 1 unit | |

| Automatic Load Sorters | 2 units | 0.1 g – 10 kg |

Molds

| Wire Cut Electric Treatment | 2 units |

|---|---|

| EDM Machine | 1 unit |

| Machining Center | 1 unit |

| Milling Machines | 12 units |

| Lathes | 5 units |

| Drill Presses | 8 units |

| Jig Grinding Machine | 1 unit |

| Optical Profile Grinding Machine | 1 unit |

| Surface Grinding Machines | 2 units |

| Forming Grinding Machines | 3 units |

| Cylindrical Grinding Machine | 1 unit |

| Tool Grinding Machines | 4 units |

| Bandsaw | 1 unit |

| Tempering Electric Furnaces | 2 units |

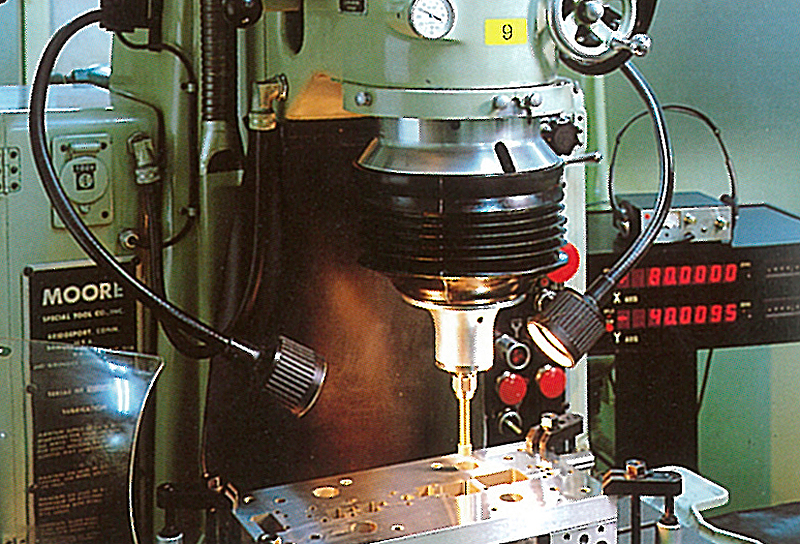

Machining Center

Machining Center

Wire Cut Electric Spark Machine

Surface Grinding Machines

Jig Grinding Machine

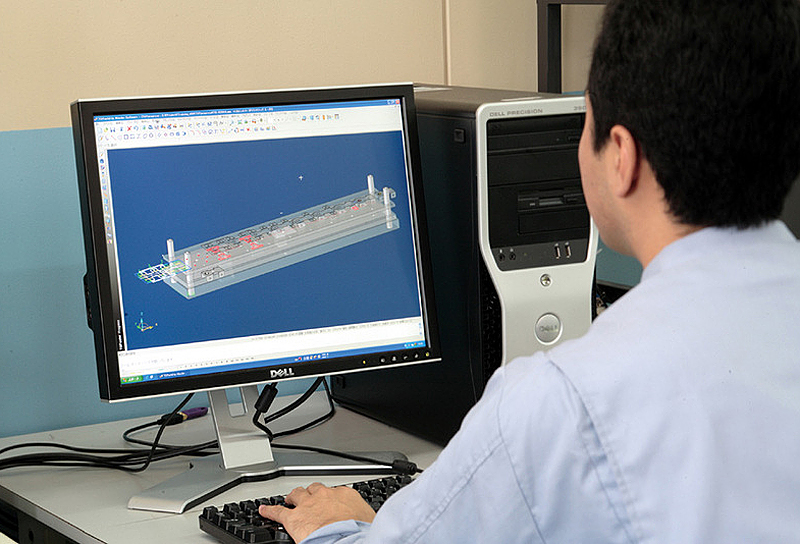

3D CAD/CAM

Welding

| Spot Welding Machine | 1 unit |

|---|---|

| Gas Welding Machines | 2 units |

| Electric Welding Machines | 2 units |

Design

| Personal 2D CAD/CAM | 7 units |

|---|---|

| 3D CAD/CAM | 4 units |